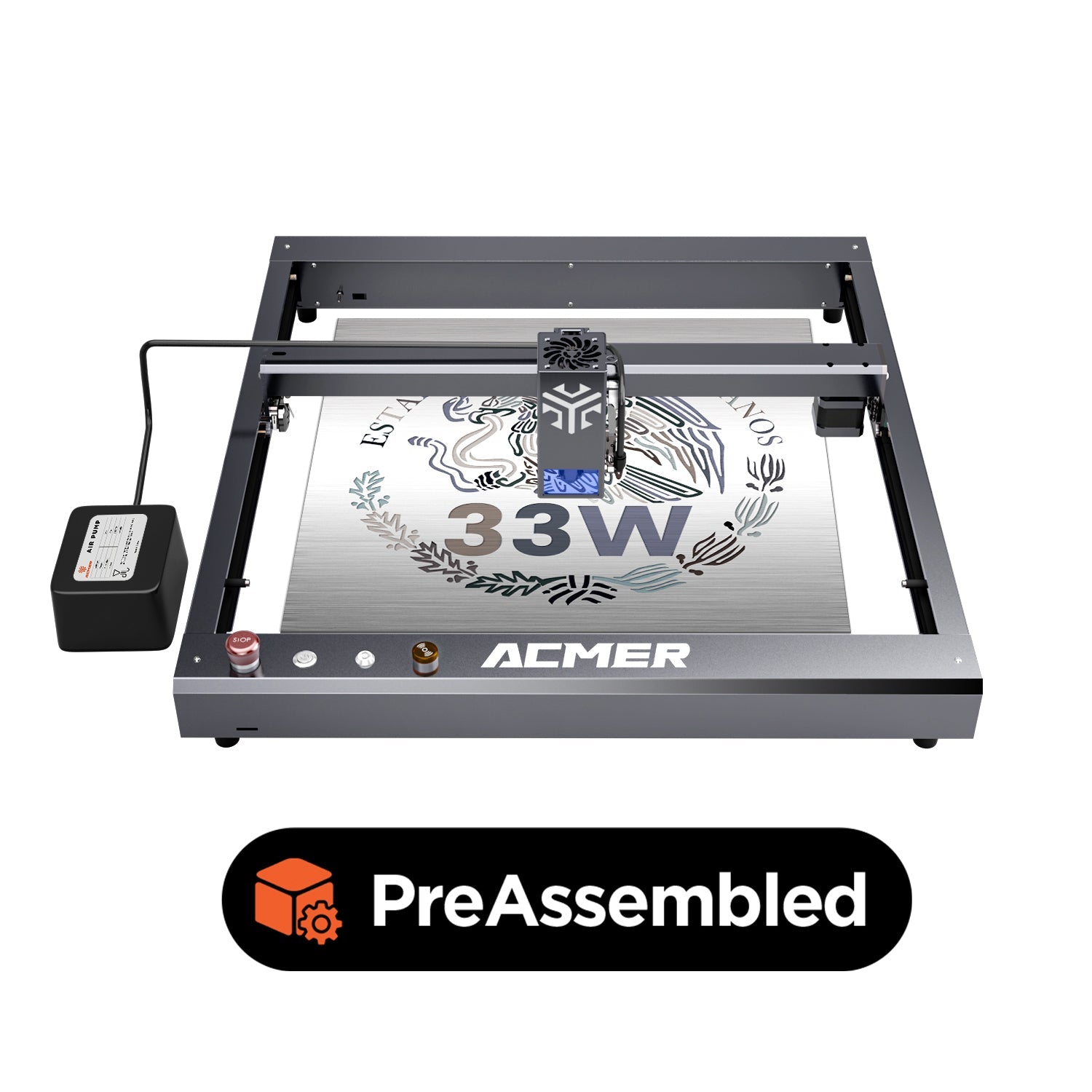

ACMER P2 33W Laser Engraving Cutter Machine

1. The bundled order may be shipped in multiple packages.

2. The machine and main accessories will be shipped from U.S. or EU.

3. Other accessories and materials will be shipped from China.

Description

- Laser output of 33-36 watts.

- Zero Assembly ready to work in just one minute.

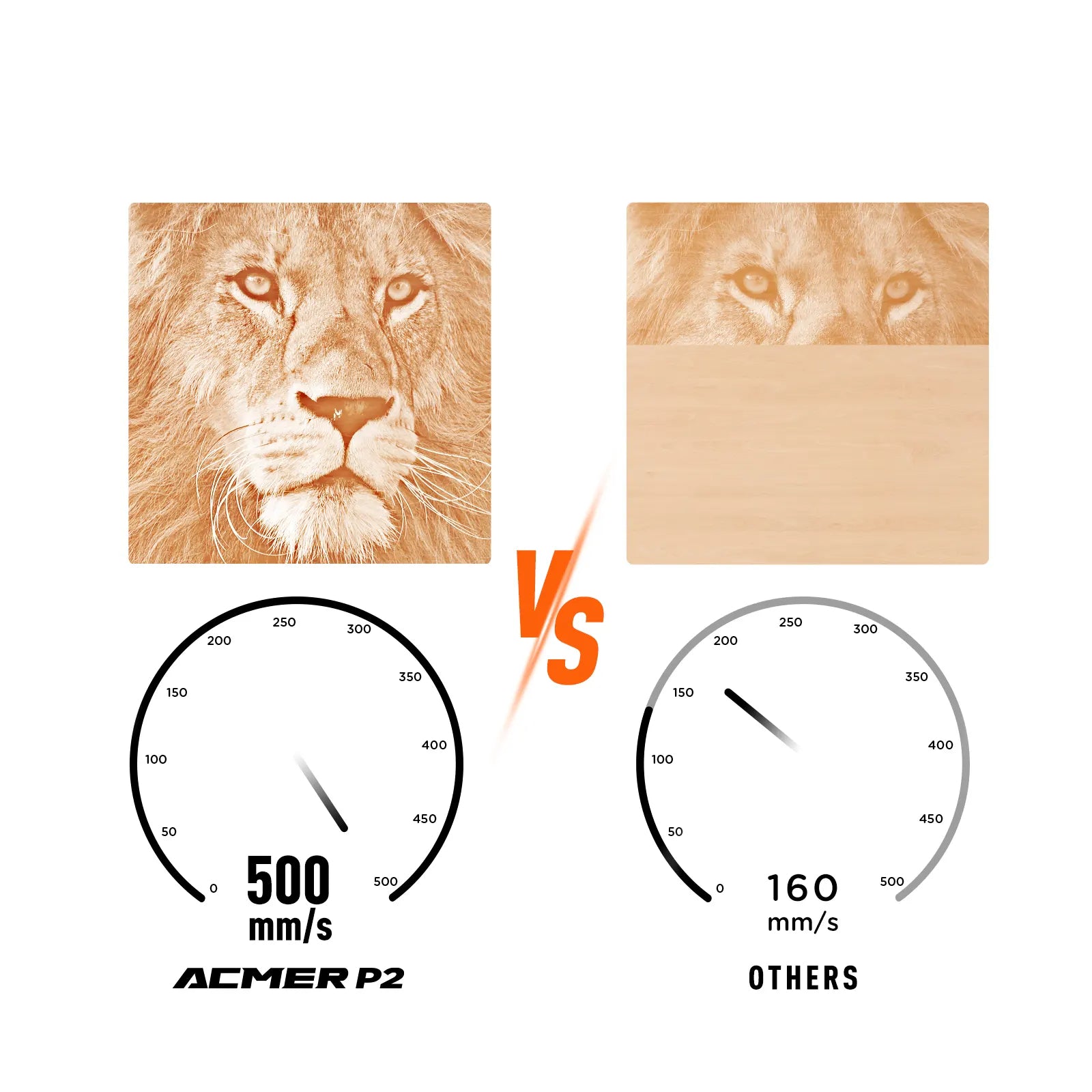

- Up to 30000mm/min engraving speed Work faster.

- Cut through 30mm wood 20mm acrylic 9mm MDF 0.1mm metal

- Support 10W/20W/33W/48W diode Laser Module and red Laser Module.

- Built-in Automatic 25L/min air assist system

-

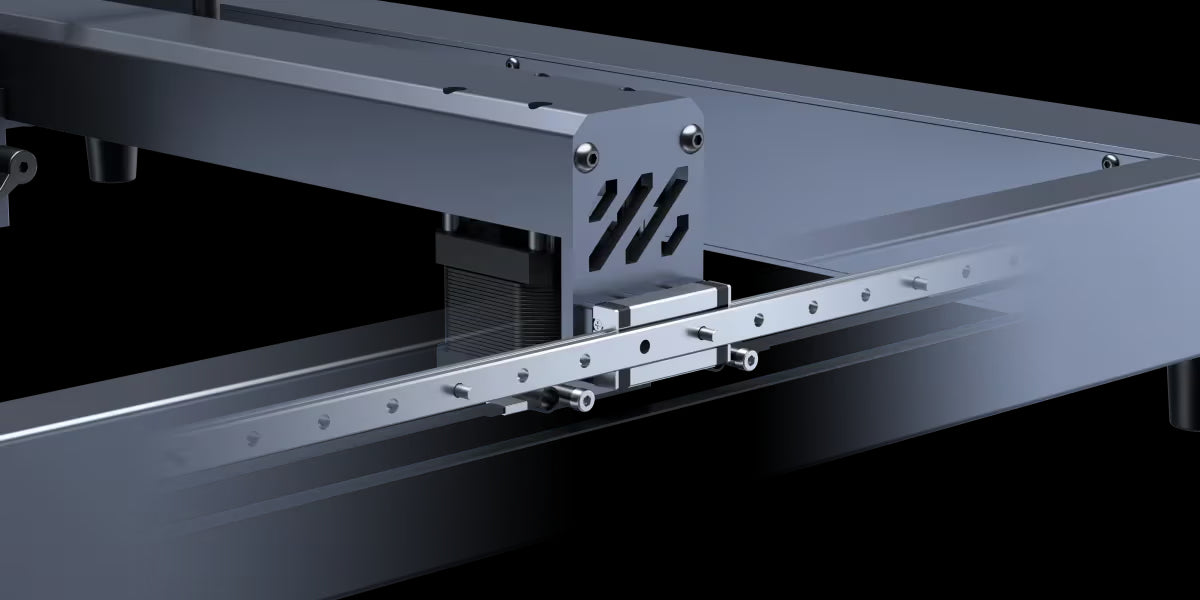

Ultra-precision Industrial Guideways for the x-axis and y-axis.

- Optional 800mm Y-axis extension kit doubles the engraving work area. up to 200%.

- Optional 1064nm laser module more suitable for engraving jewelry and gold and silver ornaments.

Package list

Machine x1

laser Module x1

air assist x1

Power Adapter x1

Machine Key x2

Laser Goggle x1

Card Reader & TF Card x1

Power Cable x1

Rotary Axis Wire x1

USB Cable x1

Brushes x1

Wrench x1

Screwdriver x4

Plywood Material

What they say about ACMER P2 33W?

Specifications

Laser Output Power:20000mw

Laser Type:Diode laser / Upgradeable 1064 laser

Machine Power:120W

Laser Wavelength:450±5nm

Power Supply:24V/4A

Focal Length:5mm

Engraving Accuracy:0.01mm

Laser Module Design Life:10000 hours

Maximum Engraving Speed:30,000 mm/min

Working Area Size:420*400mm

Assembly Method:Preassembled

Machine Size:613*590*200mm

Machine Weight:6.5kg

Movement structure:Industrial guide rail

Certification:FCC/CE/RoHS/FDA

Control Software:LightBurn/LaserGRBL/ACMER App(Android) / MKS(iOS)

Compatible Accessories:1064 laser module, ACMER P2 Engraving Area Expansion Kit, Honeycomb Laser Bed , R10 Laser Enclosure Box , ACMER M2 Rotary Roller,ACMER C4 Air Assist

File Format Supported:JPG, SVG, PNG, BMP, G-code, CAD, AI, CDR, DWG, etc.

Safety Features:Emergency stop button, Gyroscope detection(Tilt 15 degrees to automatically turn off the laser),Motherboard over-temperature protection,child safety lock,flame detector.

Parameter

ACMER P2 33W Engraving Parameters

| Material | Line Interval (mm) | Speed (mm/min) | Power (%) | Note |

|---|---|---|---|---|

| Basswood | 0.12mm | 13000 | 100 | |

| Leather | 0.12mm | 20000 | 40 | |

| Kraft Paper | 0.12mm | 20000 | 65 | |

| MDF | 0.12mm | 20000 | 65 | |

| Carton | 0.12mm | 20000 | 60 | |

| Stainless Steel | 0.09mm | 3000 | 100 | It is recommended to choose a thicker stainless steel. |

| Anodized Aluminum | 0.09mm | 15000 | 100 | |

|

Wrench (galvanized iron) |

0.09mm | 4000 | 100 | |

| Glass | 0.12mm | 20000 | 70 | Engraving is done after the material is blackened or color paper is applied to the surface |

| Ceramics | 0.12mm | 20000 | 70 | The engraving is done after the color paper is applied to the surface of the material. |

| Acrylic | 0.12mm | 20000 | 40 |

ACMER P2 33W Cutting Parameters

|

Material |

Thickness | Speed (mm/min) | Power (%) | Passes | Note |

|---|---|---|---|---|---|

| Plywood | 4mm | 600 | 100 | 1 | |

| Plywood | 6mm | 400 | 100 | 1 | |

| Plywood | 8mm | 300 | 100 | 1 | |

| Plywood | 10mm | 200 | 100 | 1 | |

| Plywood | 12mm | 100 | 100 | 1 | Focal length reduced to 2 mm |

| Bamboo | 4mm | 400 | 100 | 1 | |

| Bamboo | 8mm | 200 | 100 | 1 | Focal length reduced to 2 mm |

| Paulownia Wood | 15mm | 200 | 100 | 1 | |

| Paulownia Wood | 20mm | 150 | 100 | 1 | |

| Pine Wood | 5mm | 500 | 100 | 1 | |

| Pine Wood | 10mm | 200 | 100 | 1 | |

| Leather | 1mm | 4500 | 100 | 1 | |

| Kraft Paper | 1mm | 4500 | 100 | 1 | |

| EPE foam board | 10mm | 1000 | 40 | 1 | |

| MDF | 2mm | 800 | 100 | 1 | |

| MDF | 3mm | 700 | 100 | 1 | |

| MDF | 5mm | 200 | 100 | 1 | |

| Acrylic | 2mm | 400 | 100 | 1 | Must be black opaque acrylic to cut. |

| Acrylic | 4mm | 200 | 100 | 1 | |

| Acrylic | 6mm | 200 | 100 | 2 | |

| Acrylic | 10mm | 200 | 100 | 4 | |

| Acrylic | 15mm | 200 | 100 | 6 |

Warm Tips:

- Pay attention to the speed and power units mentioned above, and make sure to convert them appropriately in Lightburn and LaserGRBL software.

- If you're working with materials that have a low burning point, it's not recommended to set the cutting speed below 100mm/min, as it could potentially cause burning.

- Even if you're using the same material, the results can vary based on surface treatment or color. Therefore, it's important to adjust the speed and power settings according to the specific objects you're working with. Additionally, try to optimize the focal length to achieve the smallest possible focal point.

- There are certain materials that cannot be engraved or cut directly, such as glossy metal plates, transparent materials, reflective materials, and some white or translucent materials. In such cases, you'll need to darken the material with a marker before carving.

Support

Laser Engraver Assembly Manual

If you purchased a non-pre-installed version of ACMER P2 Series, you can download the Assembly Manual. for reference, and you can also watch the installation tutorial on our official youtube channel.

How to use APP to control laser engraving

If you want to control the laser engraving machine through your mobile phone as a terminal, you can read the App operation manual. You can learn how to connect to the machine via wifi. For specific IP and port settings, please read the manual.

APP Operation Manual Download Android APP

Free software to convert image for laser engraving

LaserGRBL is a highly effective Windows software for laser engraving images. With just a few clicks, LaserGRBL can load any image, picture, or logo and send it to your laser engraving machine. Specifically designed for hobbyist laser cutters and engravers, LaserGRBL is a great free and user-friendly alternative. If you're looking for a simple and efficient tool, LaserGRBL is an excellent option.

The Best Laser Engraver & Cutter Software

LightBurn is a versatile software designed for laser cutters, offering layout, editing, and control capabilities. With LightBurn, you can import artwork in a variety of vector graphic and image formats, edit and create new vector shapes, and apply settings such as power, speed, and cut order. The software supports multiple operating systems, including Windows, Mac OS, and Linux, and allows you to send your designs directly to your laser cutter.

How to Upgrade a Laser Engraver ACMER P2

ACMER P2 firmware update is an important step to ensure that your laser engraving machine performs better and has more features. To avoid errors during the update process, we have prepared a simple and easy-to-understand firmware update guide for you. Before upgrading the firmware, please make sure that you have backed up all important data to prevent data loss. The steps to update the firmware are very simple and can be completed by following the few simple steps provided in the guide. Please note that before updating the firmware, please read and understand all the steps carefully to ensure that you can complete the upgrade correctly. By following the firmware update guide we provide, you can easily complete the firmware update and get a better user experience with your laser engraving machine.

Laser Output Power:20000mw

Laser Type:Diode laser / Upgradeable 1064 laser

Machine Power:120W

Laser Wavelength:450±5nm

Power Supply:24V/4A

Focal Length:5mm

Engraving Accuracy:0.01mm

Laser Module Design Life:10000 hours

Maximum Engraving Speed:30,000 mm/min

Working Area Size:420*400mm

Assembly Method:Preassembled

Machine Size:613*590*200mm

Machine Weight:6.5kg

Movement structure:Industrial guide rail

Certification:FCC/CE/RoHS/FDA

Control Software:LightBurn/LaserGRBL/ACMER App(Android) / MKS(iOS)

Compatible Accessories:1064 laser module, ACMER P2 Engraving Area Expansion Kit, Honeycomb Laser Bed , R10 Laser Enclosure Box , ACMER M2 Rotary Roller,ACMER C4 Air Assist

File Format Supported:JPG, SVG, PNG, BMP, G-code, CAD, AI, CDR, DWG, etc.

Safety Features:Emergency stop button, Gyroscope detection(Tilt 15 degrees to automatically turn off the laser),Motherboard over-temperature protection,child safety lock,flame detector.

ACMER P2 33W Engraving Parameters

| Material | Line Interval (mm) | Speed (mm/min) | Power (%) | Note |

|---|---|---|---|---|

| Basswood | 0.12mm | 13000 | 100 | |

| Leather | 0.12mm | 20000 | 40 | |

| Kraft Paper | 0.12mm | 20000 | 65 | |

| MDF | 0.12mm | 20000 | 65 | |

| Carton | 0.12mm | 20000 | 60 | |

| Stainless Steel | 0.09mm | 3000 | 100 | It is recommended to choose a thicker stainless steel. |

| Anodized Aluminum | 0.09mm | 15000 | 100 | |

|

Wrench (galvanized iron) |

0.09mm | 4000 | 100 | |

| Glass | 0.12mm | 20000 | 70 | Engraving is done after the material is blackened or color paper is applied to the surface |

| Ceramics | 0.12mm | 20000 | 70 | The engraving is done after the color paper is applied to the surface of the material. |

| Acrylic | 0.12mm | 20000 | 40 |

ACMER P2 33W Cutting Parameters

|

Material |

Thickness | Speed (mm/min) | Power (%) | Passes | Note |

|---|---|---|---|---|---|

| Plywood | 4mm | 600 | 100 | 1 | |

| Plywood | 6mm | 400 | 100 | 1 | |

| Plywood | 8mm | 300 | 100 | 1 | |

| Plywood | 10mm | 200 | 100 | 1 | |

| Plywood | 12mm | 100 | 100 | 1 | Focal length reduced to 2 mm |

| Bamboo | 4mm | 400 | 100 | 1 | |

| Bamboo | 8mm | 200 | 100 | 1 | Focal length reduced to 2 mm |

| Paulownia Wood | 15mm | 200 | 100 | 1 | |

| Paulownia Wood | 20mm | 150 | 100 | 1 | |

| Pine Wood | 5mm | 500 | 100 | 1 | |

| Pine Wood | 10mm | 200 | 100 | 1 | |

| Leather | 1mm | 4500 | 100 | 1 | |

| Kraft Paper | 1mm | 4500 | 100 | 1 | |

| EPE foam board | 10mm | 1000 | 40 | 1 | |

| MDF | 2mm | 800 | 100 | 1 | |

| MDF | 3mm | 700 | 100 | 1 | |

| MDF | 5mm | 200 | 100 | 1 | |

| Acrylic | 2mm | 400 | 100 | 1 | Must be black opaque acrylic to cut. |

| Acrylic | 4mm | 200 | 100 | 1 | |

| Acrylic | 6mm | 200 | 100 | 2 | |

| Acrylic | 10mm | 200 | 100 | 4 | |

| Acrylic | 15mm | 200 | 100 | 6 |

Warm Tips:

- Pay attention to the speed and power units mentioned above, and make sure to convert them appropriately in Lightburn and LaserGRBL software.

- If you're working with materials that have a low burning point, it's not recommended to set the cutting speed below 100mm/min, as it could potentially cause burning.

- Even if you're using the same material, the results can vary based on surface treatment or color. Therefore, it's important to adjust the speed and power settings according to the specific objects you're working with. Additionally, try to optimize the focal length to achieve the smallest possible focal point.

- There are certain materials that cannot be engraved or cut directly, such as glossy metal plates, transparent materials, reflective materials, and some white or translucent materials. In such cases, you'll need to darken the material with a marker before carving.

Laser Engraver Assembly Manual

If you purchased a non-pre-installed version of ACMER P2 Series, you can download the Assembly Manual. for reference, and you can also watch the installation tutorial on our official youtube channel.

How to use APP to control laser engraving

If you want to control the laser engraving machine through your mobile phone as a terminal, you can read the App operation manual. You can learn how to connect to the machine via wifi. For specific IP and port settings, please read the manual.

APP Operation Manual Download Android APP

Free software to convert image for laser engraving

LaserGRBL is a highly effective Windows software for laser engraving images. With just a few clicks, LaserGRBL can load any image, picture, or logo and send it to your laser engraving machine. Specifically designed for hobbyist laser cutters and engravers, LaserGRBL is a great free and user-friendly alternative. If you're looking for a simple and efficient tool, LaserGRBL is an excellent option.

The Best Laser Engraver & Cutter Software

LightBurn is a versatile software designed for laser cutters, offering layout, editing, and control capabilities. With LightBurn, you can import artwork in a variety of vector graphic and image formats, edit and create new vector shapes, and apply settings such as power, speed, and cut order. The software supports multiple operating systems, including Windows, Mac OS, and Linux, and allows you to send your designs directly to your laser cutter.

How to Upgrade a Laser Engraver ACMER P2

ACMER P2 firmware update is an important step to ensure that your laser engraving machine performs better and has more features. To avoid errors during the update process, we have prepared a simple and easy-to-understand firmware update guide for you. Before upgrading the firmware, please make sure that you have backed up all important data to prevent data loss. The steps to update the firmware are very simple and can be completed by following the few simple steps provided in the guide. Please note that before updating the firmware, please read and understand all the steps carefully to ensure that you can complete the upgrade correctly. By following the firmware update guide we provide, you can easily complete the firmware update and get a better user experience with your laser engraving machine.

FAQs

What is the warranty period for the machine?

12 months

ls it difficult to assemble the laser engraving ACMER P2?

Very simple. The machine can be assembled within one minute.

What materials can be engraved and cut?

Include wood, plywood, acrylic, aluminum oxide, ceramics.glass, leather, slate, etc Supported cutting materials include wood, plywood, acrylic, thin metasheets, etc. ACMER engraving parameter table contains parameters for different materials.

ls it possible to upgrade the laser module, such as from 20W to 33W?

Yes, you can purchase any laser module for ACMER P2 series, including 10W and 33W, in theaccessories category.

How to lmprove the Cutting Ability of ACMER P2?

The primary factors that affect the cutting ability are the laser module's power and the auxiliary air pump. To achieve a strong cutting ability, you can consider purchasing a 33W laser module and upgrading to the gas auxiliary system ACMER C4 (30L/min). Additionally, using a honeycomb plate to assist gas circulation can be helpful.

For those who primarily focus on engraving scenes, our standard electromagnetic silent air pump that can produce an air output of 25L/min will meet your engraving needs. Any unauthorized modification of the air pump to increase its output may increase the risk of fire, unless an inert gas is used.

No assembly required, Instant startup

Streamline assembly by eliminating complex steps, providing users with a hassle-free experience. Discover the unique touch of laser engraving.

Structure determines performance! Industrial Guideways

The X-axis and Y-axis have industrial-grade linear guideways, which enhance engraving stability and accuracy through their superior structural design. Additionally, the ultra-high pixel resolution ensures a photo-quality experience.

Amazing engraving speeds!

This engraving system utilizes ACMER Lab's well-established motion control technology, capable of reaching speeds up to 30,000 mm/min. Its sturdy mechanics guarantee faster engraving times for artwork while maintaining utmost stability and ultra-high precision.

Potential for upgrading!

By incorporating various power options (10w/20w/33w/1064), the diode lasers enable a smooth transition from being a beginner to becoming a proficient laser practitioner. Moreover, the inclusion of the 1064 laser guarantees exceptional results when engraving jewelry and metal ornaments, ensuring a high level of professionalism.

Expansion kits enable greater creative space!

Take your creativity to new heights with our simple upgrade that expands your work area by up to 100%. Unlock endless possibilities as you create larger puzzles and models.

Buy Expansion KitWhy choose higher laser power

Enhancing laser power greatly enhances the capabilities of engraving and cutting, leading to a substantial increase in productivity. Furthermore, it unlocks a multitude of creative possibilities, enabling the creation of vibrant gradient effects on stainless steel surfaces.

Among 30-watt laser engravers, the ACMER P2 33W stands out as the best performer. Its light output surpasses 30 watts and reaches an impressive 33 watts, resulting in exceptional performance. The higher power level allows for a wider range of engraving applications and enables powerful cutting.

Experience the enhanced creativity that comes with the use of a 33-watt laser, which can effortlessly oxidize stainless steel surfaces, resulting in a wide range of shades.

When operating, this machine effortlessly cuts through thick materials in a single pass, surpassing the capabilities of lower-powered machines. This enables you to achieve results that exceed even your wildest expectations. Additionally, it is equipped with a standard silent electromagnetic air-assisted pump, which plays a crucial role in optimizing its performance.

Experience the enhanced creativity that comes with the use of a 33-watt laser, which can effortlessly oxidize stainless steel surfaces, resulting in a wide range of shades.

When operating, this machine effortlessly cuts through thick materials in a single pass, surpassing the capabilities of lower-powered machines. This enables you to achieve results that exceed even your wildest expectations. Additionally, it is equipped with a standard silent electromagnetic air-assisted pump, which plays a crucial role in optimizing its performance.

EmergencyStop Switch

Power Security Lock

Switchable Flame Detector

Move / Tip Instant Stop